Discovery Farm trials and demonstrations seek solutions to the challenges western Canadian farmers have identified as most pressing for both today and tomorrow. The results provide independent, unbiased information farmers can apply to the important decisions they make for their operation.

In 2019, the Field of Excellence program included a canola agronomy trial and a wheat fertility trial, both carried out with partners positioned at various points in the crop-production cycle including seed suppliers, equipment manufacturers and crop protection companies.

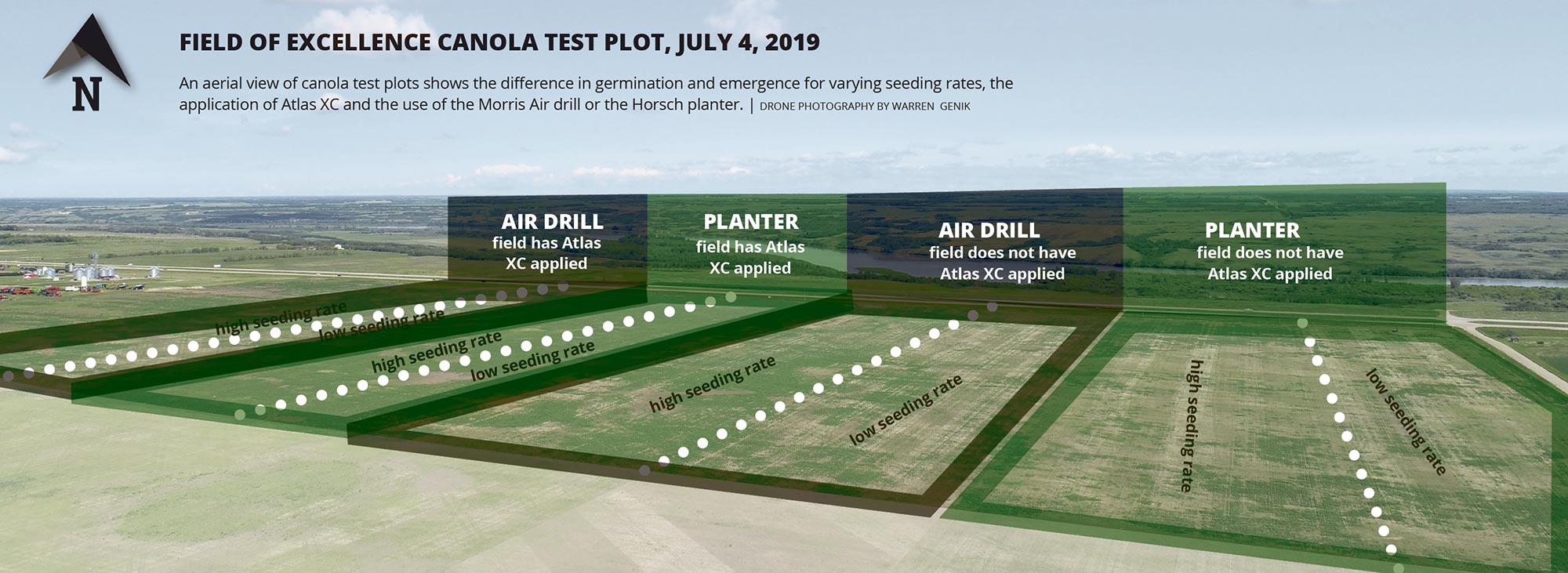

The agronomy trial recognizes farmers’ interest in canola and the need to assess a row-crop planter versus a conventional air drill. There was also interest in knowing if the precise placement of the row planter would allow producers to reduce the canola seeding rate compared to target rates for an air drill without sacrificing plant population or canopy closure.

An additional 80 acres of wheat was seeded to evaluate nutritional products emerging on the market. Atlas XC is a dry fertilizer treatment applied at the time of seeding and designed to make phosphorous more readily available to plants. The other product—Radiant—is applied with herbicide to stimulate root growth.

The results of the 2019 Field of Excellence trials were/will be released at Farm Forum Event Dec. 3-5, 2019 in Saskatoon, SK.

Research Report

A Comprehensive Research Report of the 2019 Field-Scale Demonstration Trials Conducted at the Glacier FarmMedia Discovery Farm

AGI

AGI has helped Discovery Farm become a fully functional research facility, providing grain handling and storage equipment to develop the site. “We want to support the industry,” says Dave Poppel, AGI regional sales manager for Canadian Prairies East region. “Discovery Farm is an opportunity for the industry to be better and we want to be a part of that.”

The company provided infrastructure for Discovery Farm such as Westeel bins for grain and fertilizer, a Batco conveyor and Westfield grain auger. The equipment enables Discovery Farm to partner with a wide range of ag companies to conduct live demonstrations and field tests. “As an industry, we should all be working together towards a goal of making things better. It helps to make agriculture research more relevant to farmers and consumers,” says Bev Staniland, AGI trade show specialist for farm brands.

AGI engineers and manufactures agriculture products used across all stages of crop production. Its 35 brands provide grain storage, handling and processing equipment for farmers on six continents. “What Discovery Farm offers aligns with AGI very well,” Poppel says. “It helps keep us engaged and at the forefront of ag technology. The expectations of customers change and we strive to keep up with that. At a research farm, it gives us that extra insight into what might be coming.”

With permanent infrastructure in place, AGI envisions using the Discovery Farm site for more than just showcasing its products. “When we’re out there running equipment, we can do hands-on training with farmers but also do some training with our own staff,” Poppel says.

There are more learning and training opportunities at a research farm than at test plots at a commercial farm and collaboration is key to successful research, Poppel says. “We’ve developed a great working relationship with Discovery Farm. If they need a piece of equipment, they just needed to call and we’d help out. Whether it’s our end-customers or dealer network, it’s great for them to see us making an investment not just for ourselves, but for the industry.”

Alpine

Nachurs Alpine Solutions partnered with Discovery Farm to incorporate its liquid fertilizers in field trials, a rare opportunity for the company, says brand manager Larry Balion. “When you look at fertilizer trials in Canada, hardly anyone does liquid products because there’s limited access to the necessary equipment. This was a great chance for us to showcase our product in a farm-test environment.”

One of the seeding equipment companies conducting field trials at Discovery Farm asked Alpine to contribute fertilizer and equipment as part of the project. The large scale of the field tests incorporating multiple facets of crop production give Alpine insight into how farmers use its products, Balion says. “For us, it’s good exposure through third-party testing. It tells us how our products would compare to other products in other systems.” The field tests used Alpine G22, a starter fertilizer placed in-furrow with the seed at planting. “It contributes to faster germination and allows the crop to start earlier and finish earlier,” Balion says.

Discovery Farm’s location is convenient and having Ag in Motion on site every year is great for companies looking for exposure, Balion says. “Farmers can come out and talk to us when we’re out there. That helps because a lot of times when you do large-scale trials, it’s difficult to see things in action. Having Ag in Motion at the same time makes it easy for farmers to see everything.”

Glacier FarmMedia, which owns and operates Ag in Motion and Discovery Farm, is the ideal company to partner with, Balion says. “They’re able to get the message out. We’re happy to support the project. They’re flexible at the site and open to ideas. There’s a lot of potential out there.”

Apache and Bruin Sprayers

Discovery Farm used Apache and Bruin sprayers in multiple field trials in 2019, helping the sprayer’s parent company Equipment Technologies (ET Canada) build customer relationships and forge the next generation of farmers. “Working with Discovery Farm is a huge opportunity to contribute to the ag community and ag education while showcasing our equipment,” says Eric Friesen, regional director of sales for ET Canada.

Equipment Technologies is the international manufacturer that builds Apache and Bruin sprayers. The company partnered with Discovery Farm to showcase its new Bruin HS 1100 sprayer, which was used in pre-seeding and in-crop work for canola, wheat and soybean field trials. “We took the opportunity to put the machine in the field to showcase it for our customers,” Friesen says.

Originally built for use in Europe, the new model sprayer boasts several new and retooled features for North American farmers. The self-propelled sprayer has the tallest rear boom sprayer available in North America and a 120-foot boom package. “It was incredible to run it and see how it responds before you get out with customers,” Friesen says. “It’s great for us because we can bring staff out to run a sprayer and that experience leads to better technicians and better sales teams.” Discovery Farm is accessible and staff are knowledgeable, which makes for an easy working relationship, Friesen says. “The team out there is very accommodating. We can bring a customer to the site and walk around. We’re not confined like we are at a dealership.”

Friesen says Discovery Farm can play an integral role in developing agriculture education. Discovery Farm is already partnered with Saskatchewan Polytechnic and the University of Manitoba through Stoller Enterprises. “These initiatives are great for students. They get hands on experience with equipment in real world conditions.” He sees Discovery Farm as a centre of ag innovation, where development of cutting-edge technology and education opportunities meet. “The Discovery Farm team is open to ideas and they want to learn from the industry as much as they want to share their knowledge.” The dedication to knowledge creation will help the next generation of farmers. “The technology of farming grows so rapidly so having students out there getting experience will put them at the front of the industry.”

Canada West Harvest Centre (CLAAS)

Canada West Harvest Centre is the official harvest sponsor at Discovery Farm, where the dealership lent out its new series of combines for 2019 field trials. The large-scale research farm at the newly expanded Ag in Motion site is a welcome addition to the agriculture sector, says Mike Malmgren, branch manager for Canada West Harvest Centre (CLAAS) in Saskatoon. “This is where the equipment industry is heading. Usually, we’ll take a piece of equipment to this guy’s farm and then that guy’s farm, but having a centralized location where people can learn multiple things at once is great for us.”

Developing partnerships with Ag in Motion and Glacier FarmMedia, not to mention the other ag sector companies working at Discovery Farm, helps Canada West Harvest Centre keep on top of industry trends in research and technology. “What’s good for us is good for the industry,” Malmgren says. “Any research that is advancing production technology will be good for the farmer’s bottom line and that’s good for the industry.”

Canada West Harvest Centre is the go-to dealership for CLAAS products and other harvest equipment. The company used a combine from its new CLAAS Lexion 8000 series to harvest the canola and wheat grown in field trials at Discovery Farm. Malmgren got a chance to drive the combine himself, which wasn’t just an excuse to get out of the office. “It’s great to get out in the field and work with the equipment. It’s a learning environment and some people from the office got to go out and get familiar with a combine that’ll be our flagship product in 2020.”

The company’s early experience partnering with Discovery Farm bodes well for future projects. The Ag in Motion team operating Discovery Farm is second to none, Malmgren says. “Blake and Cal and the rest of the team really took ownership of the site. They started with a bare field and they’ve built a great operation. They’re committed to what they’re doing and it’s the start of something awesome.”

Canada West Harvest Centre envisions more partnerships at Discovery Farm in the coming years. Malmgren says the company could contribute to tillage and spraying trials, or simply use the site for customer-focused days. “It’s a great venue for that. You can get outside on the field, have meetings inside, and head out in the field.” Discovery Farm has a role to play in the company’s future. “We’re a long-term industry partner and we want to give back to it. We’re here to do business.”

FCL/Co-op

The scope of Discovery Farm enables partners like Co-op to develop large-scale multi-year crop trials. “The research farm near Saskatoon is accessible and its on-site Ag in Motion staff make for great working relationships,” says Glenda Clezy, Grow Team Advisor and agronomist with Co-op. “We don’t have our own research farm so these collaborations are important. We can also take what we learn and build it into the results we’re getting from the smaller farm trials we run in partnership with growers.”

Co-op partnered with Discovery Farm on several demonstrations in 2019, testing new products and contributing to multi-partner crop trials. Co-op planted multiple varieties of barley and canola, tweaking the process with different seed treatments and seeding depths to test growth under different stress conditions. The canola field trials compared seeding with an air drill against seeding with a row planter, while herbicide layering demonstrations showcased weed management applications. Four soybean varieties were also planted, in part to familiarize staff with what is still a relatively new crop in Western Canada. “For a product we might not be selling yet, we can get results over a couple years and determine if it is a good fit or not for our Co-ops,” Clezy says. “Or these might be crops people aren’t familiar with so they get the opportunity to see them in the ground and learn best practices.”

The partnership also helped Co-op to advance its sustainability initiative Grown With Purpose. In the field trials at Discovery Farm, Co-op looked at crop management systems focused on soil health, enhanced efficiency fertilizers, and proper fertilizer placement. “It helped us illustrate initiatives in our Grown with Purpose platform that promote sustainability and proper fertilizer management across Western Canada,” Clezy says.

Co-op organized two visits to Discovery Farm that brought together retail agronomists to talk about the trials. “It’s an opportunity for them to see a variety of different systems and operations in one place and benefit from hands-on learning.” The year-round access and proximity to Saskatoon also enables Co-op to bring out farmers and trade groups to visit with retailers. “It’s a bonus when they can walk through the plots, see and feel the products,” Clezy says. “It’s a Co-op site, not a supplier site. This type of research and demonstration site helps build confidence with local Grow Team members and customers.”

Horsch

With more growers interested in soybean and corn crops in Western Canada, ag manufacturer Horsch partnered with Discovery Farm to field test its new row planter series against the more common air drill. Field tests in real-world growing conditions is the best way to showcase a product for growers, says Horsch product manager Jeremy Hughes. “This gets us close to our customers. The whole Discovery Farm concept is to engage farmers in those conversations that mean most to them, and that’s basically, what is going to make a profit?”

At Discovery Farm, 140 acres were divided into 16 blocks to field test different combinations of treatments and “low” and “high” seeding rates with the Horsch Maestro SW planter and a Morris Quantum air drill. The Maestro planter seeded canola at 190,000 and 220,00 seeds per acre. The Quantum air drill seeded canola at 220,000 and 435,000 seeds per acre. Nitrogen was applied at seeding. Treatments were applied pre-seeding and again at planting using a “starter” liquid nitrogen. The trial used Atlas XC biocatalyst and Radiate to stimulate root growth.

The large, multifaceted demonstration enabled growers to see for themselves how equipment and treatments work together at different stages of crop production. “This is a good chance to get a snapshot,” Hughes says. “People can research online all they want, but at the end of the day you need to touch and feel and see to have a good understanding of it. Overall, we were very pleased with the results.”

The field trial found that the type of seeding equipment did affect canola emergence, with average plant stand counts higher for the planter and treatments than the air drill. But there was no measurable difference in emergence between the planter and the air drill at the 220,000 seeds per acre rate with the use of Atlas XC. Without Atlas XC, there was a slightly higher emergence for planter compared to the seeder.

The yield differences between the planter and air drill were minor, but slightly higher yields were observed in treated fields seeded with the planter. The seeding rate used for both types of equipment did not seem to impact yields. The planter and air drill achieved acceptable crop yields at the “low” seeding rates. “At the end of the day, every farmer needs to make a decision about what’s best for their operation,” Hughes says. “There’s a lot of different concepts out there and no single concept works for everybody.”

With increasing interest in row planters, Discovery Farm was the perfect place to test the Maestro SW planter in real-world growing conditions, Hughes says. “It’s a challenge to managing test plots and trials on this scale. One of the attractive things about Discovery Farm is the people. These are timed events that need to happen and having a team out there to manage it is great.”

Morris

Today’s farmers have access to more data and technology than ever before. Live trials and demonstrations help cut through the noise, says Steve Liebel, director of marketing for Morris Industries, a Discovery Farm partner. “It’s beneficial for farmers to see with their own eyes. You don’t get this type of a hands on environment at a lot of ag shows. It’s even better when the demonstrations go beyond the shows where equipment is operated in real growing conditions.”

The Saskatchewan-headquartered Morris Industries has manufactured and sold farm equipment around the world since 1929. Morris recently launched the Quantum independent opener hoe drill, featuring a redesign of the company’s familiar flat pan distribution air system and a new stainless steel head design that reduces row-to-row variance. Morris partnered with Discovery Farm to use the Quantum air drill in canola and soybean trials this past year.

Four sections of the field were used to test how changing the seeding rate or fertilizer application affects growth and yields. The trial also tested the pros and cons of using a row-crop planter versus a conventional air drill. Half of a 140-acre canola field was seeded with a Morris air drill and the other half with a Horsch planter. Morris also seeded 80 acres of soybeans in recognition of Western Canada’s increasing interest in the crop. “Soybeans are relatively new to Western Canada,” says Morris Industries corporate agronomist Garth Massie. “It’s still considered a somewhat experimental crop in central Saskatchewan, probably because it’s a longer growing season. But lately there have been some advances toward a shorter growing season. We want to show the capability of our products to meet the challenges.”

Massie used the company’s Quantum air drill in the soybean trial, the first time he got to use Morris Industries equipment to seed soybeans. “That is valuable hands-on experience for the company,” Massie says. The field test experimented with combinations of treatments and “low” and “high” seeding rates. The Morris Quantum air drill seeded canola at 220,000 and 435,000 seeds per acre with nitrogen applied at seeding.

The yield differences between the planter and air drill were minor, but slightly higher yields were observed in treated fields seeded with the planter. The low and high seeding rates used for both types of equipment did not seem to impact yields. There was no measurable difference in emergence between the planter and the air drill at the 220,000 seeds per acre rate with the use of Atlas XC. Without Atlas XC, there was a slightly higher emergence for the planter compared to the air drill. “I wouldn’t go betting the farm on the results,” Liebel says. “These were terrible growing conditions because of the drought, but we were in the same situation as farmers. That’s the long-term benefit of Discovery Farm. We can replicate the trial next year under different conditions and see what happens.”

For Morris Industries, Discovery Farm isn’t just a place for showcasing new products. It also provides opportunities to help employees and dealerships. “There are all sorts of offshoots, like dealer training. It’s not just profiling new products. It provides a platform for us to do different things we might not have the resources to do,” Massie says. “For us to do our own tests like this, it would take considerably more effort. We didn’t have to worry about lining up spraying or harvesting.”

Nutrien Ag Solutions

It didn’t take much to convince Nutrien Ag Solutions, a long-time Ag in Motion exhibitor, to partner with the new research farm. The company (formerly Crop Production Services) is keen to explore the research and education possibilities at Discovery Farm, says Cynthia Deitz, Proven Seed brand manager with Nutrien Ag Solutions. “We’re excited to work closely with Discovery Farm because there is a great vision for what they want to accomplish out there. Because this is a working farm, it allows us to focus on our products and all the things we can do for farmers. It’s all there.”

The Nutrien Ag Solutions field trials looked at aspects of crop fertility and seed genetics. Specifically, Nutrien wanted to look at nutrient uptake for canola crops using two treatments—Radiate and Atlas XC—and how they affect yields. Half of the crops received treatments and the other half was left untreated. At Discovery Farm, 140 acres were divided into 16 blocks to field test different combinations of treatments and “low” and “high” seeding rates with a row-crop planter and an air drill. For the canola field trials, Atlas XC biocatalyst and Radiate were applied to stimulate root growth.

The field trial found that Atlas XC had a positive impact on canola germination. While Atlas XC appeared to have minimal impact on crop yields this year, it clearly demonstrated a positive impact on quick and even crop emergence in unseasonably dry conditions. Similarly, Radiate appeared to have minimal impact on yields. With the early emergence with Atlas XC treatments, the research team observed measurable differences in crop maturity, with Atlas XC-treated fields swathed 17 days before fields without the treatment. Given the cool, wet weather throughout September and October, it’s notable that the Atlas XC fields were harvested 21 days before the untreated fields.

Field trials on a large-scale that mimic what farmers might do with their own crops can reveal new insights into crop production. Deitz says. “Some of the things they may see might not be what our own research can tell us. We’re feeding the future and you can’t make a better future if you don’t test things out. This type of program supports making things better and educating people about how to manage resources.”

Companies are always testing products, but aligning the field trials with education goals makes it more worthwhile. “Students get to play with your products and that is the best way for any company to recruit and get familiar with their products in a real world setting,” Deitz says. “They can question what they’re seeing and be part of the testing process and applying new technology.”

Discovery Farm is owned and operated by Ag in Motion’s parent company, Glacier FarmMedia. There’s a confidence around projects when Glacier FarmMedia’s roster of ag and marketing experts are involved, Deitz says. “Discovery Farm is very interested in the digital side of the industry. The ag industry is moving so fast on the technology side. Glacier FarmMedia has experience running successful shows and their leadership team has a great grasp on where the industry is going.”

Precision.AI

Agriculture start-up Precision.AI is using drones to revolutionize automated farming and the company is field testing its technology at Discovery Farm. For an ag tech company, access to a facility like Discovery Farm helps the research and development phase for start-ups, says Precision.AI founder and CEO Daniel McCann. “It’s essential for brand new entrants in the market. If you’re a new company with a great idea, these types of facilities willing to work with innovators can have a huge impact.”

Precision.AI is field testing its autonomous sprayer drones that run on an artificial intelligence system able to differentiate between weeds and crops. The drones, which come in ground and aerial models, move up and down the rows spraying weeds as they are identified. McCann says the automated drone uses a small nozzle to spray individual weeds, which improves efficiency because a farmer isn’t also spraying the crops and surrounding ground.

At Discovery Farm, McCann tested the targeting engine by running the drone through a canola crop at different stages of growth. Tests also measured accuracy at different speeds and times of day. With Discovery Farm operating from seeding through harvest, companies get a chance to test their products in real-world growing conditions. “It’s not staged and it’s not lab conditions. Farming is so dependent on weather and different factors that you need to have the real world testing to advance the technology and be confident in your product,” McCann says.

Creating ideal research conditions for testing isn’t always easy. For example, Precision.AI had to let weeds grow in the canola fields to test the artificial intelligence system’s ability to differentiate between weeds and canola. “When you don’t have a research-type facility, that becomes problematic because farmers are actually using their land but you want to use their land for research. Having land available to us where we could do what we need to do to advance the technology in actual growing conditions is extremely valuable.”

Precision.AI will be at Discovery Farm again next year fine tuning its technology as the company moves toward commercial production. The capability for testing across multiple seasons or years is great for research and development. “Different environmental conditions and different seasons will present different pests or ratios between crop staging so it helps improve your product. In the technology game you’re never done innovating. You have to test in the real world.”

Stoller and University of Manitoba

The longtime collaboration between Stoller Enterprises and the University of Manitoba came to Discovery Farm to study how technology can improve crop emergence and yields for farmers across Canada.

Stoller and the U of M have worked together for about four years on projects aimed at improving crop production in Canada, specifically how to improve crop emergence through the application of plant hormones. At Discovery Farm, the field test focused on Stimulate, a combination of three primary growth hormones: auxin, gibberellic acid, and cytokinin. “We hear from growers that emergence is a big problem because of the stress experienced by the seed early in the season,” says Kipp Workman, national sales and business development manager for Stoller Enterprises Canada. “Stress limits the potential for harvest, so we’re looking at how the use of stress reducing hormones can affect the yield and the return on investment for growers.”

The idea is that if root growth is “stimulated” early in the growing season, then “the roots become stronger, and stronger roots translate into better overall yield.” The field test applied Stimulate to lentils, resulting in an increase of three to four bushels per acre compared to lentils not treated with Stimulate. Similar results were observed in the company’s own winter greenhouses trials. “It’s encouraging to see consistent results across the greenhouse and Discovery Farm test plots,” Workman says.

Discovery Farm is the ideal place for developing and testing new technology, says Mark Belmonte, a professor in the Faculty of Science at the University of Manitoba. “The Discovery Farm site acts as a hub. Ag in Motion is where all the new technology debuts and where growers from all sectors looking for the next best thing in innovation come together. Discovery Farm brings together the research, the science, the growers and business side into a central location. You can’t beat that location.”

The capabilities of Discovery Farm ensure the field tests lead to meaningful results that researchers and farmers can rely on, Belmonte says. “We can take these products and dig deep into how they work and why they work in real world conditions.” Partnering with educational institutions strengthens the ag industry, he adds. “It’s a great opportunity for students working in a lab to get real world experience. Understanding how ag innovation works can eventually help growers across Canada.”

Discovery Farm is owned and operated by Glacier FarmMedia. Having an independent company operate the research farm is great for the ag industry and consumers, Workman says. “We do a lot of research on our own. Sometimes that’s discounted because it’s ours. It’s great to partner with a third party. There’s a nice distance so the growers know the results can be trusted.” With more unique products in the pipeline at Stoller, there’s plenty more years of research ahead at Discovery Farm, Workman says. “The research farm has already beat our expectations of what it could be.”